TELEGRAMS

ARMOLG MELBOURNE

TELEX CODE

AA30943

TELEPHONE 317 9001

POSTAL ADDRESS

PRIVATE BAG

PO ASCOT VALE

VICTORIA 3022

C"1E:MHC:MMM

IN REPLY TO

CHIEF SUPERINTENDENT

QUOTE

1005-Y67-16

AUSTRALIAN ARMY

DESIGN ESTABLISHMENT

RALEIGH ROAD

MARIBYRNONG

VICTORIA 3032 3047

28 Apr 72

AHQ(Mat Develop)

For info: AHQ(Inf)

SASS

MODIFIED L1A1 RIFLE 7.62mm - RMC STAFF CADET PROJECT

References:

A. SASS reference 1340-R1-14 dated 7 Oct 71

B. D Eqpt reference 1005-M67-57 dated 21 Oct 71

C. D Eqpt reference 1005-M67-57 dated 24 Jan 72

1. Herewith technical report by ADE on the "Staff Cadet Project - Modified L1A1 Rifle 7.62mm".

2. It should be noted that considerable effort had to be alloted to this task at the expense of EDL projects, and that as a matter of routine this is undesirable unless the subject really warrants this degree of effort, which this item did not.

Original signed by

(A.T.S. GARDINER)

Chief Mechanical Engineer

for Chief Superintendent

|

WPNS:MHC:MMM

A TECHNICAL REPORT BY ADE ON

L1A1 RIFLE 7.62mm AS MODIFIED BY STAFF CADET LOUGHREY

AS AN RMC STAFF CADET PROJECT

Background

1. SASS has been assisting Staff Cadet LOUGHREY who undertook as a second class project (the) modification of the L1A1 Rifle to produce a shorter weapon.

2. With the assistance of the Small Arms Factory, LITHGOW, a rifle has been produced conforming externally to Staff Cadet LOUGHREY's design.

3. SASS states that because of the excpense involved in production of a new trigger mechanism the rifle has been fitted with a standard well-tried design (presumably by LITHGOW); and that Supply would be quite happy to go further with the weapon if the Army was interested.

4. SASS asked the D Inf if the Infantry Centre and subsequently the MGQ Branch could evaluate the weapon. As the result of this request it was determined that ADE should first examine the weapon to:

- establish if Staff Cadet LOUGHREY's design was technically sound, and

- if technically sound, then examine the safety of the system to see if it could be cleared for User evaluation, and

- give a technical opinion on the weapon.

General

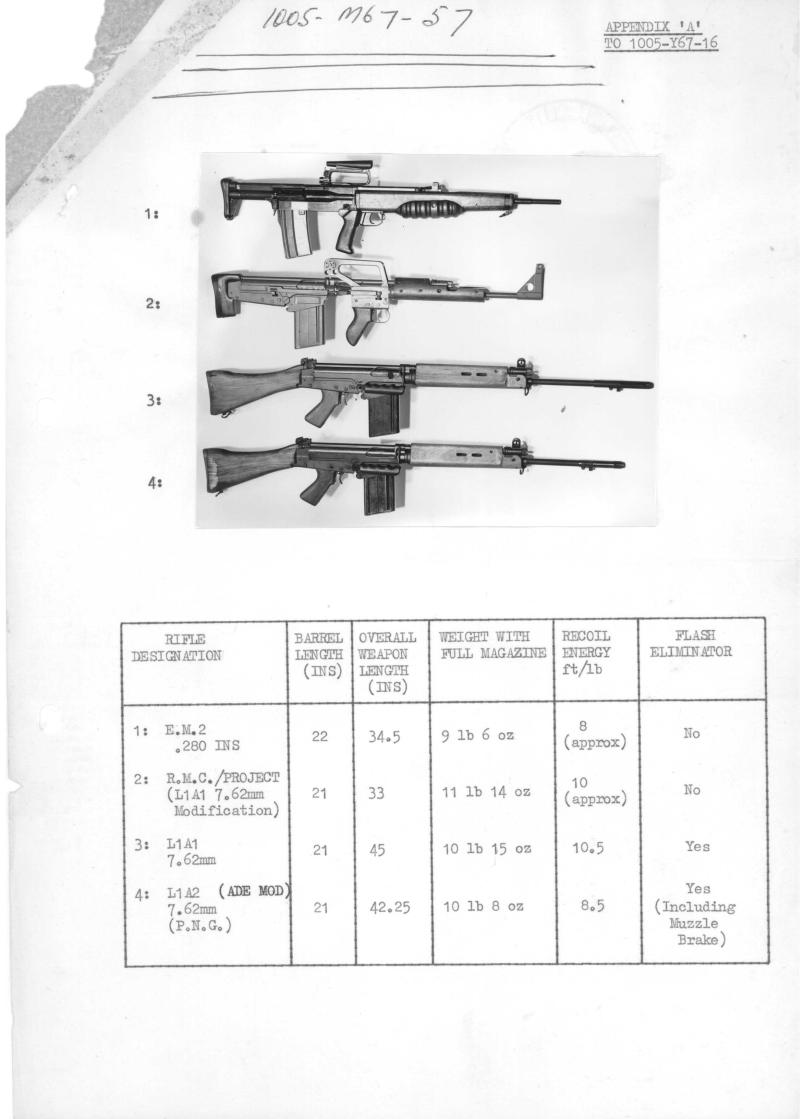

5. The concept of the modification to the L1A1 rifle by Staff Cadet LOUGHREY, copies the configuration of the UK EM2, .280 rd experimental rifle of the 1949/51 era. The EM2 was a revolutionary concept around which the whole weapon system, method of operation, locking, feeding, trigger mechanism and sights were designed to provide an ideal configuration for a "straight through" reaction of barrel axis to the firer's shoulder, achieving an ideal balance and weight to provide a very accurate and handly weapon. Obviously it is impracticable to build this configuration and ideal around an existing rifle system which belongs to an earlier, very conventional concept and configuration, to which its origninal basic mechanism was fundamental. See comparative photographs at Appendix 'A'.

6. As originally designed by FN, the L1A1 Rifle was of pre-second world war concept, belonging to the first generation of successful service self-loading rifles, and like most of its contempories had conventional machine gun type, heavy mechanisms, but unlike them, used gas operation to unlock the mechanism only, and therefore depended on case projection to complete the operating cycle, the piston only travelling a short distance and not heavy and robust as in a machine gun with a gas operated long piston stroke mechanism which drives the breech block for its complete operating cycle. The modification produced has connected the existing piston to the breech block carrier, and wrapped the return spring around the piston in place of the piston spring, with the intent of both producing a shorter weapon and changing the operating system into a long stroke gas operated weapon. The components whose operation have been changed and added to by this concept should be over stressed and will fail in fatigue accordingly, and the reliability, safety and performance of the system remain unknown withou considerable experimental firing.

../2

|

2.

7. The LOUGHREY/SAF modification by completely duplicating the trigger mechanism and joining their operation by an intermediate trigger bar, together with the heavy carrying handle, and forward trigger housing, sight bracket and heavy foresight bracket has increased the weapon weight by one pound, making it unacceptably heavier that the L1A1 rifle rather than lighter; as well as being badly balanced.

8. The trigger mechanism of this modification merely consists of a duplication of the existing L1A1 Rifle system in front of the magazine, the two trigger mechanisms being connected by an operating bar. The trigger mechanism modification is necessary because the existing locking and operating mechanism was never designed for a forwared trigger location, hence the weapon weight distribution is change and balance upset accordingly. The reliability and safety of the original signle trigger mechanism, acting directly between trigger, hammer and firing mechanism is negated, and the trigger function fo the trigger disconnector and making it inoperable after one shot unless the trigger bar is operated manually since the forward trigger mechanism trigger spring has insufficient energy to return both trigger levers through their connecting trigger operating bars.

Detail

9. The detailed comments on the design concept are as follows:

- Handling

- Hands will be burnt both by:

- the barrel which is exposed in the area of the pistol grip, and

- by the gas cylinder exposed under the carrying yoke,

- by the gas block and regulator port which is exposed in the centre of the handguards,

- by the outside of the barrel chamber when the cocking handle is grasped.

- The modification is so much heavier than the SLR and so badly out of balance, that the handling has been worsened rather than improved by the new configuration. The modified rifle weighs 11 lbs 14 ozs and the SLR 10 lbs 15 oz both with a full 20 rd magazine.

- The new configuration has placed the ejection opening in a very dangerous location in relation to the firer in both shoulder and off handshooting as follows:

- in the offhand firing position from the hip the right hand firer's arms and body will be in line with the ejector opening and the path of the ejecting case, and the left handed shooter will not be able to use this posit8ion at all as the ejection opening will be against his body,

- when shootring from the shoulder, the right handed firer will have his eye and cheek adjacent to the ejection opening, when his eye relief is correct fo rthe sifght, will tush stand a chance of losing his eye from the spent case, particular with an incorrect gas setting or faulty ejection. The left handed shooter will not be able to use the srifle from the shoulder at all since the ejection opening will be covered by his face.

../3

|

3.

.a.(contd)

- Having aimed the concept configuration at producing a straight through reaction between the axis of the barrel and the firer's shoulder to minimise the turning moment during firing, it is not clear why the centre of the butt is still below the axis of the barrel. In any case the weight of the rifle has been so increased that the recoil energy will have been minimised largely negating the geometry problem any way, the main purpose of which is to enhance controcl of a very light weapon, capable of automatic or burst fire from the shoulder.

- Exposure of the trigger bar, connecting the two trigger mechanisms is very vulnerable and very subject to damage causing non-operation of the system; this has already occurrred in the experimental model.

- The handguard situated aroudn the exposed gas regulator will cause the firer's hand and fingers to be struck by the hot exhausting gases and propellant particles.

- The foresigth bracket is vulnerable and with the permaent carrying handle integral with the rearsight bracket in their present design configuratino is prone to catch in foliage and other environmental hazards.

- The handability of the modified rifle both in the carriage and firing positions is very uncomfortable indeed, and will undoubtedly effect the speed and efficiency of its effective performance under operational conditions.

- The firer's hand and ears are now only 23.1/2 inches, including the correct eye relief from the muzzle, as opposed to 36 inches with the standard rifle, therefore the noise and pressue level effect on the firer's ears will be unacceptably high(more than double), not forgetting the standard flash eliminator reduces the level compared to a bare muzzle.

- The complete removal of the flash eliminator from the muzzle will make the rifle less tactically acceptable as an Army solution.

- Attachments

- The alteration to the configuration of the rifle, with the placement of a high foresight bracket on the muzzle, makes the use of standard current attachments, grenade launcher, bayonet, blank firing attachments etc. impossible.

- The effect of the compensator hole in the foresight bracket has not been determined, but will probabaly increase the degree of flash visibility.

../4

|

4.

9. (contd)

c. Method of Operation

-

In spite of the changes carried out to the original design concept, the original method of operation will persist, gas to unlock hence case projection, since most of the gas driving the piston is released to atmosphere immediately it has given an impulse to the piston, both through the gas regulator and the cyulinder gas release holes. The fact that the piston is now permanently arrached to the carrier only means that it becomes a return spring rod after initial unlocking, will become heavily stressed during firing and subjected to severe shock loads both during the unloadingand loading strokes, both at the point of connectino with the carrier (groove and pin) and on going to battery, when, if the relationship of the piston operating length to carrier forward limit is not carefully controlled and checked during firing the piston face with contract the gas plug face with the full momentum of the carrier and breech block effect, driving the gas plug out of its gas block seating.

d. Mechanical Safety

-

The original L1A1 Rifle mechaical safety depended on the free travel of the carrier before unlocking could commence (approx 1/2 inch). Since the piston was not connected to the carrier and it only travelled a short distance, it had come to rear before the carrier returned to battery and the rebound of the carrier was negligible as it was resisted by the return spring rod. In this suggested design, with the return spring operating through the piston, and the piston being connected to the carrier, the piston will move through this whole operating stroke, carrying the carrier to battery through the loading stroke with the whole effect of the stored energy in the return spring now operating around the piston. Because of this there will be a tendancy for piston bounce, and therefore if the weapon was fired at full automatic, particularly at elevation this bounce could be sufficient to prematurely and dangerously unlock the breech, after the cap is struck since the carrier will have already released the safety sear on its forward travel, which is another mechanical safety which prevents the hammer from being released until the carrier is fully home. Most gas operated machine guns and automatic rifles have to have either a floating piston or inertia pellet for this reason; clearly highspeed cine films would have to be taken to discover the degree of piston bounce now introduced into this modification, which may not necessarily be critical.

e. Applied Safety

-

The new duplicated trigger mechanism uses the standard applied safety in each trigger mechanism; clearly it is undesirablefor the firer to have to operate two applied safeties, and the important one which can positiviely prevent firing, is the rear one which is part of the conventional firing mechanism, and this is nowhere near the firer's trigger hand.

../5

|

5.

9. (contd)

f. Magazine Catch

-

The magazine catch which wuold originally be operated by the firer's trigger hand without removal from the trigger is no longer in a convenient location for either of rthe firer's hands, this will effect IA's as well as handling.

g. Trigger and Firing Mechanism

-

The existing L1A1 Rifle (FN Design) firing and trigger mechanism caters for a conventional weapon configuration and relationship of trigger to magazine location.

-

Many of the basic FN rifle concepts are related to their shotgun development and production, depending similarly on a conventional firing train, of trigger, sear, hammer and floating firing pin sequence, all of which are situated well behind the breech block and carrier in their locked position, this therefore causes major problems and excessive additional compon9ents if conversion to an EM2 configuration is contemplated, as in this case. It is the fundamental problem which makes it impossible to make a tidy, reliable and economical conversion of the conventional L1A1 rifleas has been attempted in this case.

-

The self-loading characteristic is achieved in the standard L1A1 rifle by interposing a disconnector device between trigger lever and sear which disconnects the trigger operation after each shot, and is reconnected only when the trigger is released and operated by the trigger spring and plunger. Since this spring and plunger have been omitted from the fundamental firing and trigger mechanism in this conversion, the disconnector remains disconnected unless the operating rod connecting the two triggers together is operated manually, because the forward trigger spring has insufficient energy to carry ou this dual function through the connecting rod.

h. Vulnerability

-

This conversion has introduced many vulnerable components, all of which could cause weapon failures and malfunctioning in service such as:

- Exposed gas cylinder tube.

- Trigger operating rod and levers.

i. Sights

-

The sights are both vulnerable in the handling of the weapon, liable to catch readily in any foliage, and the backsight carrying handle configuration completely blocks the firer's field of view.

j. Stripping

-

The attachment of the piston to the carrier and the location of the foresight bracket makes simple stripping and cleaning in the field very difficult.

../6

|

6.

9. (contd)

f. Summary

-

It would not be feasible to analyse all the effects of these fundamental design changes, on the life, reliability, function-ability of the weapon mechanism and operation service suitability without extensive firing trials.

-

It can be deduced however that the total design changes suggested as superimposed on the original design would certainly not be acceptable, particularly in terms of suitability, spares, standarization, tooling, production costs etc, at this stage in the life and time frame of the existing rifle.

-

It is doubtful if this weapon would be effective at all in terms of handability, reliability, suitability and weight increases; and is completely contrary to the user's current requirements in this respect.

-

The trigger mechanism produced by the designer of the modifications may have been better than that produced by SAF, LITHGOW, which is completely unacceptable in reliability and safety from a service point of view.

g. Conclusion

It is the conclusion of ADE that this project does not warrant any further professional effort, either technically or from a User trials point of view, as the experiment is no more than a configuration about an unacceptable vehicle for this type of conversion. In its present form it is an experimental model, which confirms the fallacy of trying to superimpose a new design on a basically out dated and different system.

Original signed by

(M.H. CHIVERS)

Small Arms Project Officer

|

1005-M67-57

APPENDIX 'A'

TO 1005-Y67-16

RIFLE

DESIGNATION |

BARREL

LENGTH

(INS) |

OVERALL

WEAPON

LENGTH

(INS) |

WEIGHT WITH

FULL MAGAZINE |

RECOIL

ENERGY

ft/lb |

FLASH

ELIMINATOR |

1: E.M.2

.280 INS |

22 |

34.5 |

9lb 6 oz |

8

(approx) |

No |

2: R.M.C./PROJECT

(L1A1 7.62mm

Modification) |

21 |

33 |

11 lb 14 oz |

10

(approx) |

No |

3: L1A1

7.62mm |

21 |

45 |

10 lb 15 oz |

10.5 |

Yes |

4: L1A1 (ADE MOD)

7.62mm

(P.N.G.) |

21 |

42.25 |

10lb 8 oz |

8.5 |

Yes

(Including

Muzzle

Brake) |

|