Kevin Loughrey

BALLINA AUSTRALIA 2478 (ABN 96 078 508 264) Ph: +61 416 276 624

"Helping others to have a future assures our own."

- Home

- Past Projects

Calibration Mgmt Sys

Kevin Loughrey

BALLINA AUSTRALIA 2478 (ABN 96 078 508 264) Ph: +61 416 276 624

"Helping others to have a future assures our own."

Calibration Mgmt Sys

Calibration Mgmt Sys

Calibration Management Information System

Background

In 1987, 27 District Workshop in Warminster, England, was (and most probably still is) the largest District Workshop in the United Kingdom's Ministry of Defence. I was posted to it as an exchange officer in late 1987; my appointment being 2nd in Charge (2IC) and the Production Manager. The workshop not only repaired the equipment of all units located in the South West of England, a major client being the local School of Infantry, but also undertook programme repair and overhaul work for the entire Ministry of Defence. As a consequence, every conceiveable type of equipment was repaired there, ranging from weapons, large and small, to vehicles of all sorts to microscopes and electronic test equipment.Calibration of Test and Measuring Equipment.

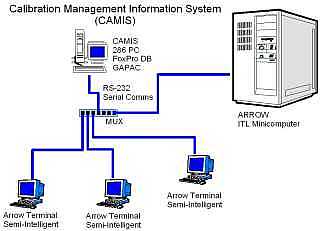

A significant function carried out in this workshop was the periodic calibration of all the medical and dental as well as the test and measuring equipment held by the military units located in the South West of England. To assist with this function, there was a system, called CAMIS. It was comprised of a small ITL mini-computer with three dumb terminals connected to it and a staff of approximately 2 personnel to administer it. The CAMIS ITL minicomputer was housed in an air-conditioned room and held a database that contained a list of all of the units served by 27 District Workshop, along with all of the equipment that required calibration, details of previous calibrations performed on each equipment, and dates when each equipment was due to be serviced again.

Before - CAMIS - Manual Data Transfer

After - "The Calibration Management Information System"

CAMIS.

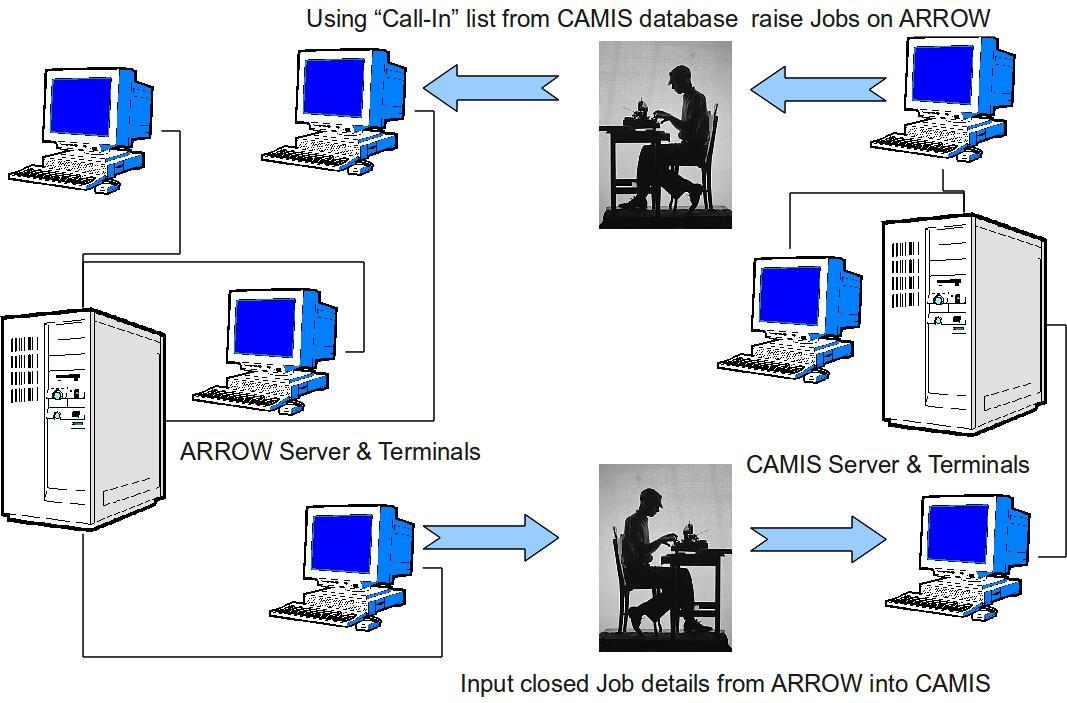

CAMIS would, on a periodic basis, produce a hardcopy list of the equipment that had to be calibrated. At 27 District Workshop, there was another computer system called ARROW. It also ran on an ITL mini-computer, much larger than the one used for calibration management. The purpose of ARROW was to assist the planning and execution of workshop jobs and to provision the spare parts necessary to effect the repairs. The staff would manually raise a workshop job for each equipment that had to be calibrated from the list. As a consequence of creating the job, a "call-in" notice would be sent to the unit holding the equipment to ensure it was taken to 27 District Workshop for calibration. Once the calibration job had been completed, the details of the job would be manually entered into the Calibration Management System and new date for recalibration entered into the database.My Background

At my previous posting, I'd been the Commanding Officer of 1 Base Workshop Battalion, located at Bulimba in Brisbane. It had a Perkin Elmer 32-20 mini-computer that ran an application called MAWD (standing for Machine Assisted Workshop Documentation). MAWD was similar to ARROW but did not manage stores because (stupidly) in the Australian Army, repair parts are managed by the Supply organisation. Spare Parts were managed on another Perkin Elmer minicomputer running an application called SCUBA; standing for Stock Controlled Usage Based Articles.Bob Willcox and his Team

When I arrived at 27 District Workshop with all of these ideas as to how the local workshop computer systems could be improved, the system administrator, Bob Willcox, at the time regarded me with some scepticism and possibly even suspicion. British Officers were notoriously non-technical. I think Bob was worried I would break something and he would be left holding the pieces. After a while though, as I started to burrow into the problems and show Bob I knew what I was doing, he and his assistant, Doug Bonner became caught up in the excitement of discovery and creation. Without them, and they were incredibly talented, adept persons, it is unlikely I would have enjoyed the success I did. As a first project, we introduced a Tray-store ordering system that utilised PSION organizers, Hewlett Packard barcode wands and IBM PCs connected to the ARROW network (without the permission of the REME Data Centre!).CAMIS - The Calibration Managment Information System

Doug Bonner had a friend, Brendan McKeever, who lived locally and was very good with computers and databases; particularly the FoxPro database, a database that behaved like Ashton Tate's DB4 except it could be compiled and did not require users to buy a runtime licence for every program that was run on a different computer. Thanks to Brendan's generosity and Doug's native ability, Doug learnt how to program in FoxPro in the space of a few weeks. I wrote the necessary software to emulate a person raising calibration jobs on the ARROW Computer and to check if the jobs had been completed. When they were completed, my software would download the job data for automatic input into the FoxPro database. I also wrote the software necessary to download all of the data out of the CAMIS ITL computer for input into the FoxPro database that Doug had written. In the space of three months we had the system working perfectly. This system was so successful, it was adopted throughout the whole of the British Ministry of Defence. The REME Data Centre, the organisation then responsible for systems development, had estimated the new CAMIS would take 5 years to develop and introduce and had budgeted 15 man years of effort to complete the project. Not only did my staff and I, part time, complete the project in 3 months, we also produced a far superior result to that which the REME Data Centre had planned. This initiative saved the British Army well over £3 million Sterling in equipment, facilities and programmer's wages. It also saved £60,000 Sterling per annum in manning costs from that point onwards. The system ran for 15 years.Savings Achieved

All manual scheduling and all manual transcription of data between ARROW and CAMIS was elimintated. The PC used for CAMIS was a 20MHz 286 with a 40MB hard drive. It cost £1,000 Sterling. The ITL minicomputer planned for CAMIS was to cost £100,000 Sterling. The PC operated in a normal room. The ITL computer required a dust-free airconditioned room. There was no longer any need for clerks to run the CAMIS computer. The workload could be coped with by the existing ARROW Staff. There were approximately 20 sites that would have had to be equipped with CAMIS.